Artificial Intelligence (AI) and 3D printing are transforming industries and manufacturing on a global scale. When combined, these technologies create a powerful synergy that is revolutionizing design, production, and innovation. AI improves every stage of the 3D printing process, from generating complex designs to enhancing quality control and automating workflows. This combination is accelerating product development and enabling customization in ways traditional manufacturing cannot match.

What’s Happening & Why This Matters

A notable breakthrough has been achieved by researchers at the University of Illinois Urbana-Champaign. They demonstrated an AI system capable of identifying the exact 3D printer that produced a given object by detecting subtle “fingerprints” embedded in the print. This method enhances supply chain transparency and product authentication. It provides companies with reliable ways to verify the origin of parts and maintain strict quality standards.

Leading companies like HP and startups such as AiBuild are developing AI-powered tools that turn simple text prompts into optimized 3D models ready for printing. HP’s “Text to 3D” system produces multiple design variants within seconds, saving engineers from tedious trial and error. AiBuild’s software predicts material behavior and generates efficient toolpaths, streamlining multi-axis manufacturing. These solutions accelerate design cycles and minimize material waste, thereby reducing costs and shortening time-to-market.

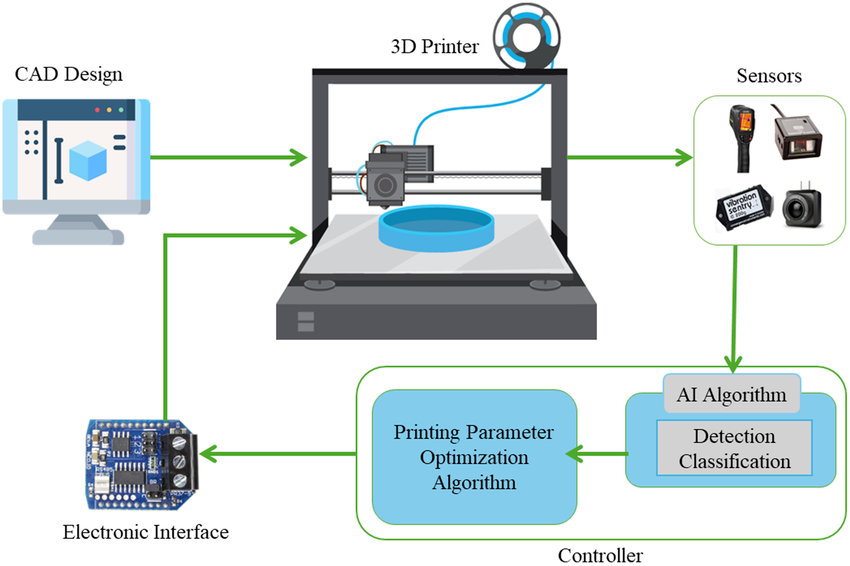

AI also improves 3D printer reliability. Traditional 3D printers often encounter common issues such as filament jams, layer misalignment, and temperature fluctuations. Integrating AI with camera and sensor data enables real-time fault detection and correction during printing. This reduces errors and scrap rates, delivering consistent print quality. AI-based systems also simplify the printing process for beginners by automating slicing and adjusting parameters, making high-quality 3D printing more accessible to them.

Furthermore, AI-equipped 3D printers can learn from every job they perform. They adjust print settings according to material types, environmental conditions, and user feedback. This adaptive learning reduces failures and optimizes resource usage. For example, printers can modify cooling times and print speeds in response to humidity changes or filament composition, ensuring better results even for inexperienced operators.

The combination of AI and 3D printing benefits a diverse range of sectors. In healthcare, personalized prosthetics and surgical guides tailored to individual patients are produced more quickly and accurately. Aerospace industries use AI to design lightweight, durable components that meet strict performance and emission standards. Fashion designers utilize these technologies to create intricate, one-of-a-kind structures that combine form and function.

Impact and Outlook

The convergence of AI and 3D printing is reshaping manufacturing and product design. This pairing enables the creation of highly customized products, reduces waste, and accelerates development cycles. As these technologies mature, we can expect fully automated manufacturing workflows that design, produce, and inspect parts with minimal human intervention.

Future 3D printers will likely incorporate advanced self-maintenance capabilities, identifying mechanical issues before failures occur and optimizing production continuously. This will empower manufacturers to deliver tailored, small-batch products at scale, enhancing customer experiences across industries.

Industry leaders anticipate that AI-driven 3D printing will become a cornerstone of digital manufacturing, powering innovations in everything from consumer electronics to industrial machinery. Organizations that invest in these technologies stand to gain a competitive advantage through improved efficiency, agility, and product quality.

TF Summary: What’s Next

The fusion of AI and 3D printing opens new frontiers in manufacturing and innovation. With AI-enhanced design, quality control, and automation, 3D printing is becoming faster, wiser, and more precise. This trend will enable companies to create personalized, high-performance products while reducing environmental impact.

As we experience faster adoption, TF expects continued AI improvements in models and printing hardware, fueling a new era of agile and sustainable manufacturing.

— Text-to-Speech (TTS) provided by gspeech