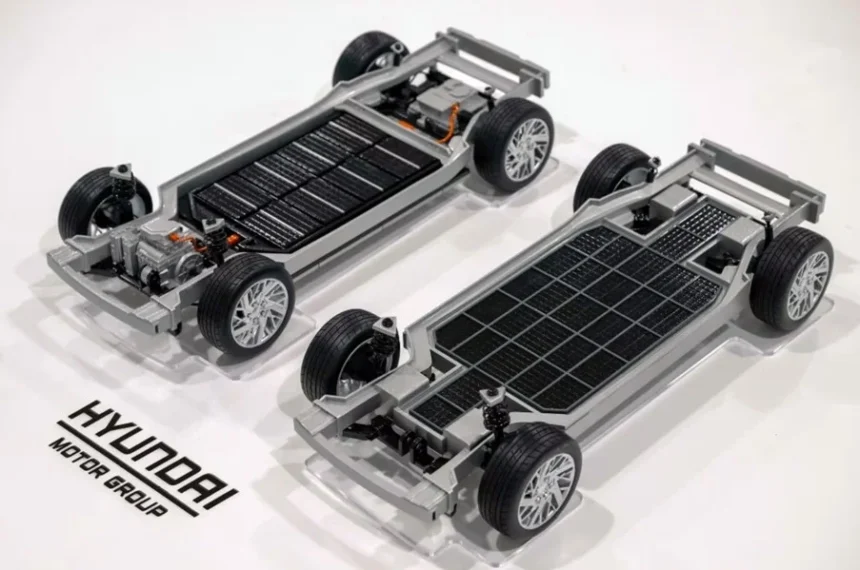

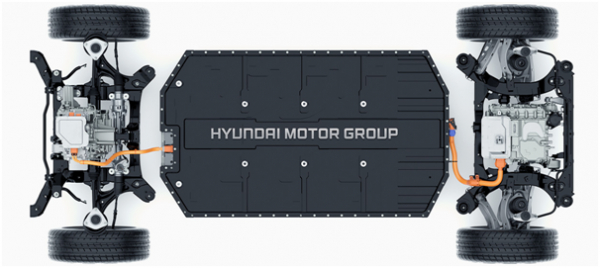

Hyundai and Kia are collaborating on an ambitious project to create more affordable, fast-charging batteries for electric vehicles (EVs). Both companies are already known for offering some of the most competitively priced EVs on the market, such as the Hyundai Kona and the Kia EV9. This new initiative is designed to reduce the cost of EV batteries, using lithium iron phosphate (LFP) technology, while improving performance, particularly in cold weather and fast-charging scenarios.

What’s Happening & Why This Matters

The Hyundai-Kia Battery Project

Hyundai and Kia are taking a bold step to make electric cars even more affordable by developing lithium iron phosphate (LFP) batteries. LFP batteries have become increasingly popular among automakers like Tesla, Ford, and Rivian, who use them in their entry-level models to keep costs down. Unlike traditional nickel cobalt manganese (NCM) batteries, which are more expensive, LFP batteries offer a lower-cost alternative while still providing good performance.

The four-year development project is expected to streamline the manufacturing process by eliminating a production step, which will make these batteries more cost-effective to produce. Hyundai and Kia are working closely with two key partners in this endeavor: Hyundai Steel, a Korean steel manufacturer, and EcoPro BM, a company that specializes in battery materials.

Focus on Performance and Fast-Charging Capabilities

While affordability is a major focus, the performance of these LFP batteries, especially under specific conditions, is equally important. One challenge with LFP batteries is that they typically perform less efficiently in cold weather compared to NCM batteries. Hyundai and Kia are addressing this issue by developing LFP cathode material that enhances charging and discharging capabilities, even at low temperatures. The project aims to achieve fast-charging technology that can deliver a high level of performance in all weather conditions.

Reducing reliance on imports, especially from China, is another important goal of this project. China currently leads the global battery market, particularly in LFP technology. Chinese company CATL, for instance, has already introduced next-generation LFP batteries that can deliver 250 miles of range in just 10 minutes of charging. Hyundai and Kia’s efforts could help reduce dependency on Chinese manufacturers and establish more local control over the battery supply chain.

The Road Ahead

While Hyundai and Kia have not yet announced when these new battery packs will become available, industry predictions suggest that the demand for fully electric vehicles will grow significantly by 2030, driven in part by advancements like these. In the meantime, Hyundai is exploring other battery technologies, with plans to introduce an “extended range electric vehicle” (EREV) in 2026, capable of providing up to 560 miles of range through a combination of gasoline and electric power.

TF Summary: What’s Next?

The Hyundai-Kia partnership to develop affordable, fast-charging LFP batteries is a savvy move in the electric vehicle industry. By improving the efficiency and cost of these batteries, both companies are trying to make electric vehicles more accessible to more consumers everywhere. With a focus on both affordability and performance, this project has the potential to expand EV demand through the decade.