Ford is betting big on making electric vehicles more affordable through its new Universal EV platform. The automaker just unveiled its $5 billion Universal EV project. The platform is built for durability, lower cost, and adaptability. The first model, a mid-sized electric pickup truck, is slated for 2027 with a starting price near $30,000. This price is about half the base cost of today’s F-150 Lightning.

What’s Happening & Why This Matters

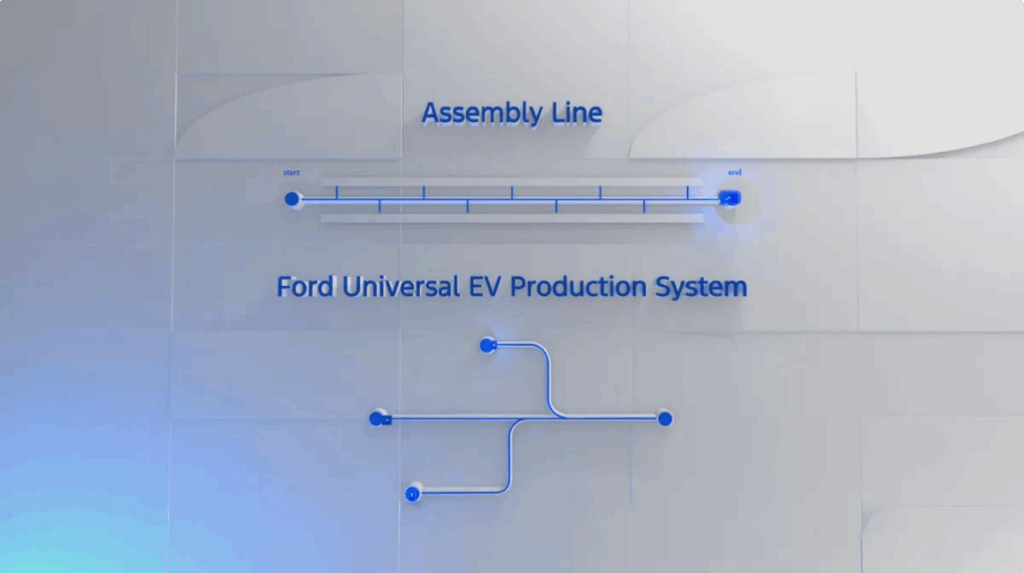

Ford’s approach centers on the Universal EV platform using lithium iron phosphate (LFP) batteries, assembled in the U.S., and a modular build process. This approach reduces parts and speeds up assembly. The goal is clear: make EVs that are practical, long-lasting, and available in multiple body styles for work, play, and export.

President and CEO Jim Farley calls the project a breakthrough in affordability and adaptability. “Ford is going to deliver what no other automaker has been able to: a family of affordable, adaptable electric vehicles,” he said. He stressed that LFP batteries will be made in America, not imported from China.

Why LFP Matters

LFP batteries are reshaping the EV market. They cost less, take up less space, weigh less, and last longer than traditional nickel cobalt manganese (NMC) batteries. They also avoid cobalt and nickel — materials often sourced from regions with questionable labor and environmental practices.

While LFP can underperform in cold weather, Ford plans to address this through design updates. Updates like battery warmers will be implemented. Industry experts note the extended lifespan: University of California, Berkeley’s Scott Moura estimates LFP packs can last 200,000 miles. This is two to three times the charge cycles of NMC. That longevity means fewer replacements and lower total ownership costs.

Building Smarter, Faster

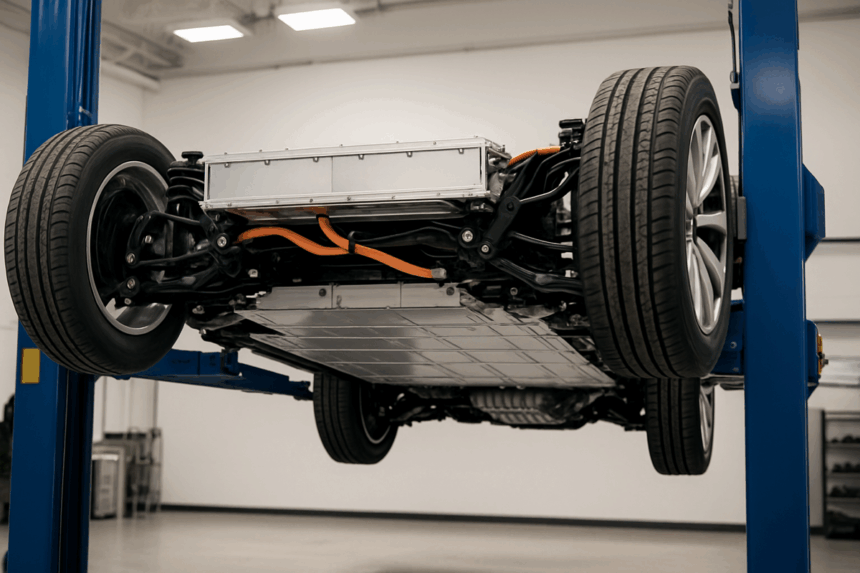

Ford’s new assembly method uses the battery pack as the structural core of the vehicle in its Universal EV platform. The front and rear are built separately, then attached to this central unit. This reduces parts by 20%, cuts fasteners by 25%, requires 40% fewer workstations, and speeds assembly by 15%.

The automaker will produce the first trucks at its Louisville Assembly Plant. Ford is investing $2 billion in upgrades with support from Kentucky’s state government. Ford is also spending $3 billion to scale LFP production at BlueOval Battery Park in Michigan.

Competing Globally

Farley credits Tesla veterans Doug Field and Alan Clarke with creating a propulsion system efficient enough to rival Chinese EV giant BYD. “Our battery could be so much smaller than BYD’s,” Farley told Wired.

Farley has firsthand insight into China’s EV strength. He imported a Xiaomi SU7 sedan from Shanghai last year. “I’ve been driving it for six months now, and I don’t want to give it up,” he admitted on the Fully Charged podcast.

Pricing Reality Check

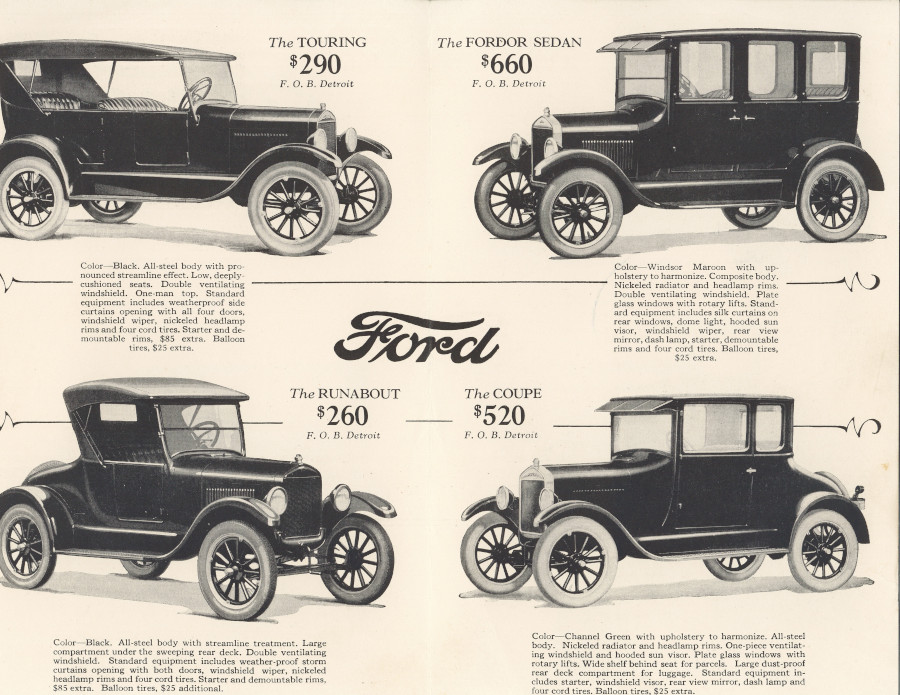

Ford’s $30,000 target echoes the inflation-adjusted price of the Model T, but history offers caution. The F-150 Lightning launched under $40,000, only to see multiple price increases due to supply chain challenges and high demand. The question remains whether the Ford Universal EV platform can hold the line on cost while scaling production.

TF Summary: What’s Next

Ford is betting $5 billion that LFP technology and streamlined assembly can redefine EV affordability. If the company delivers on its $30,000 promise, the Universal EV platform could reorient the market for consumers. It could benefit fleet buyers, too.

The coming years will test whether Ford can outpace global rivals and keep prices stable in a volatile supply chain. The true measurement will be in 2027 — when the first truck rolls off the Louisville line. Will buyers decide if this “Model T moment” meets expectations?

— Text-to-Speech (TTS) provided by gspeech