AI Demand And Global Trade Tensions Squeeze Critical Metals Supply

The next wave of tech price hikes may not come from chips or memory. It may come from metals. Copper shortages and rising tin prices threaten the cost of PC components, cooling systems, and data center hardware.

Industry leaders warn that supply disruptions and global stockpiling have sharply driven up raw material prices. AI demand accelerates the pressure. Tariff fears amplify it. Manufacturers are preparing for another round of consumer price increases.

This is not a theoretical risk. It is already happening.

What’s Happening & Why This Matters

Copper Prices Surge on Supply Constraints

Copper prices rose from roughly $9,000 per ton to $13,000 per ton year over year. That represents an increase of nearly 50 percent in U.S. dollars. In euros, the increase stands closer to 30 percent. Even at that lower figure, the jump is dramatic.

Roman Hartung, CEO of Thermal Grizzly, explains the situation in detail. His company produces high-performance cooling components used in PCs and data centers.

In October, Hartung attempts to order 12mm copper plates. The normal price sits around 190 euros with a delivery time of one to two weeks. The supplier quotes 280 euros and a four-month wait.

That is not a marginal fluctuation. That is a supply shock.

Hartung describes the increase as “absolutely massive for one year.”

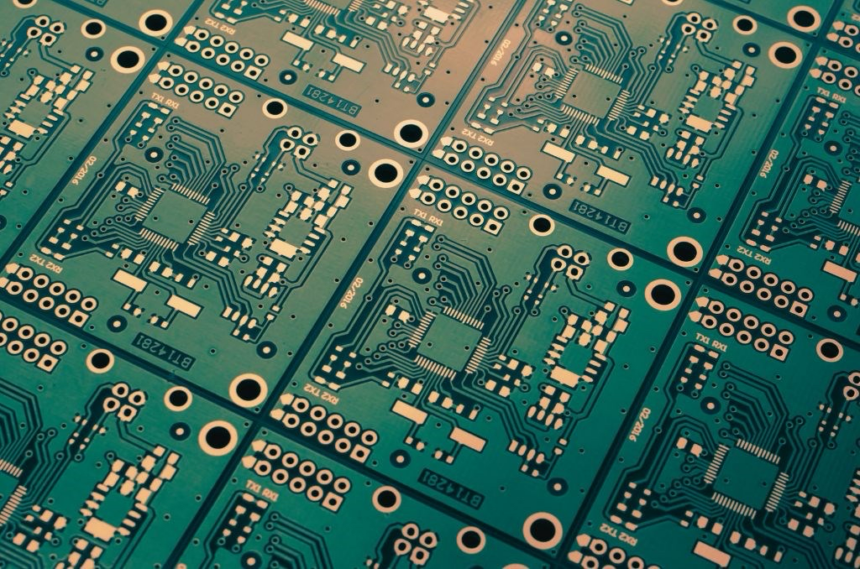

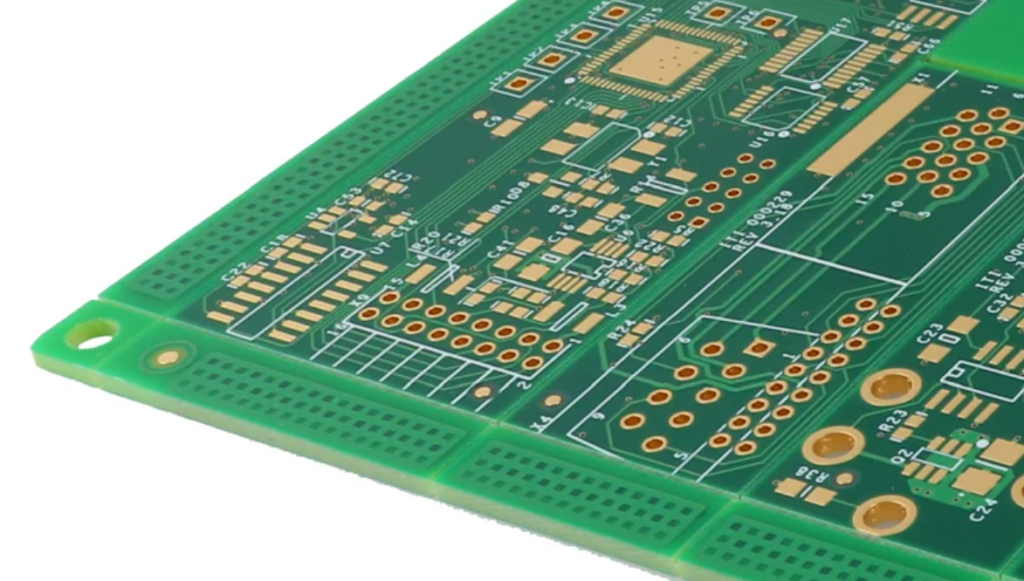

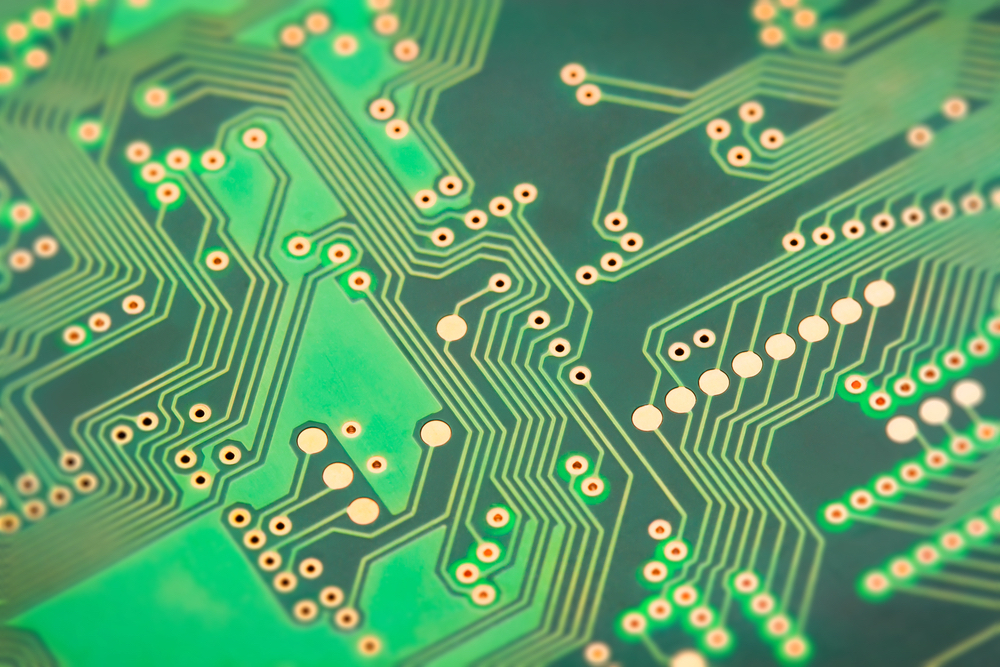

Copper touches nearly every part of electronics manufacturing. It carries electricity through wires and forms printed circuit boards. Copper transfers heat away from GPUs and CPUs. It’s inside power supply units. When copper is in flux, the entire tech stack feels it.

Tin Prices Climb Even Faster

Tin prices rose even more sharply. In euros, tin climbed roughly 60 percent. In U.S. dollars, it climbed around 80 percent.

Tin has a quiet but vital role, too. Manufacturers use it in solder. Without solder, chips do not connect to boards. Components do not communicate, leading systems to not function.

RoHS-compliant solder, required under environmental regulations, costs nearly triple what it once did, according to Alphacool CEO Andreas Rutnicki.

Rutnicki states,

“Unfortunately we are compelled to adjust prices by the end of February by approximately 5-10% across all products.”

He stressed that copper-based products are most affected. Price adjustments have already begun.

AI Computing Demand Drives Structural Pressure

AI changes the demand curve. Data centers are expanding. GPU clusters are multiplying. Cooling systems must scale up. Every AI server requires copper for power distribution and cooling infrastructure. Every printed circuit board relies on copper traces. Solder joints depend on tin.

As AI model training accelerates, hardware demand surges. That demand pulls more raw materials into hyperscale buildouts.

Hartung connects the dots directly. The increased demand for AI compute contributes to copper scarcity.

This dynamic creates a feedback loop. AI drives hardware expansion. Hardware expansion increases copper demand. Higher demand tightens supply. Prices rise. Consumers pay more.

Tariffs, Stockpiling Alter Global Supply

Trade policy compounds the issue. Hartung points to U.S. tariff policies under President Donald Trump as a catalyst for material stockpiling. Companies anticipate further tariff increases. They move aggressively to secure copper inventory inside the United States.

Hartung explains,

“They drained warehouses in China and Europe.”

He clarifies that global copper reserves remain relatively strong. The issue centers on distribution. Copper shifts geographically toward the U.S., leaving shortages in Europe and Asia.

He notes,

“Just because you have globally a lot of copper doesn’t really help if you have local shortages.”

This is a logistics problem layered on top of demand pressure.

Currency fluctuations add another variable. Hartung also observes that the U.S. dollar weakens in part due to political developments, further complicating international pricing dynamics.

The supply chain becomes fragile when policy, currency, and demand converge.

Some Materials Are Stable — Momentarily

Not all metals follow the same trajectory. Aluminum and nickel increase only around 5 percent. Steel prices actually decline.

That divergence highlights how copper and tin occupy a uniquely critical position in electronics manufacturing.

You can substitute steel in some applications. You cannot easily replace copper in circuit boards or high-performance cooling blocks.

Price Hikes Spread

Thermal Grizzly prepares to raise GPU water block prices from about 500 euros to roughly 550 euros.

Other manufacturers echo similar concerns. Be Quiet! CEO Aaron Licht states that his company currently maintains stable pricing. However, he warns that persistent raw material inflation may force reevaluation.

Meanwhile, Alphacool is already committed to increases across its catalog. The pattern signals early-stage inflation for components.

When cooling hardware rises, GPU accessories increase. The trickle effect continues. When solder rises, motherboard costs spike. Materials trickle into components. When motherboard costs rise, finished PC prices jump.

Consumers may soon feel it.

For The Tech Economy…

The tech industry already navigates memory price cycles and chip shortages. Raw materials join the list.

Copper underpins the electrification economy. It powers EVs, renewable grids, AI data centers, and consumer electronics. A prolonged copper shortage could ripple across industries far beyond PCs.

Meanwhile, tin shortages affect compliance-certified manufacturing processes. That limits flexibility.

If AI infrastructure expansion continues at the current speed, raw material competition intensifies. That tension pushes companies to secure long-term contracts, diversify their supplier base, and invest in recycling technologies.

The conversation moves from semiconductors to base metals. The supply chain narrative grows more complex.

TF Summary: What’s Next

Copper shortages and rising tin prices pressure electronics manufacturers worldwide. AI demand amplifies the stress. Tariff policy reshapes distribution. Companies begin adjusting prices.

In the short term, expect incremental increases across cooling systems, PC components, and possibly GPUs. In the medium term, manufacturers will seek regional diversification and recycling solutions. Over time, copper supply expansion projects may stabilize markets. Yet those projects take years.

MY FORECAST: If AI infrastructure expansion continues at current velocity, copper becomes a strategic commodity on par with semiconductors. Investors track mining capacity. Governments revisit trade strategy. And consumers brace for steady component inflation rather than temporary spikes.

The metal under your motherboard may soon matter as much as the chip on it.