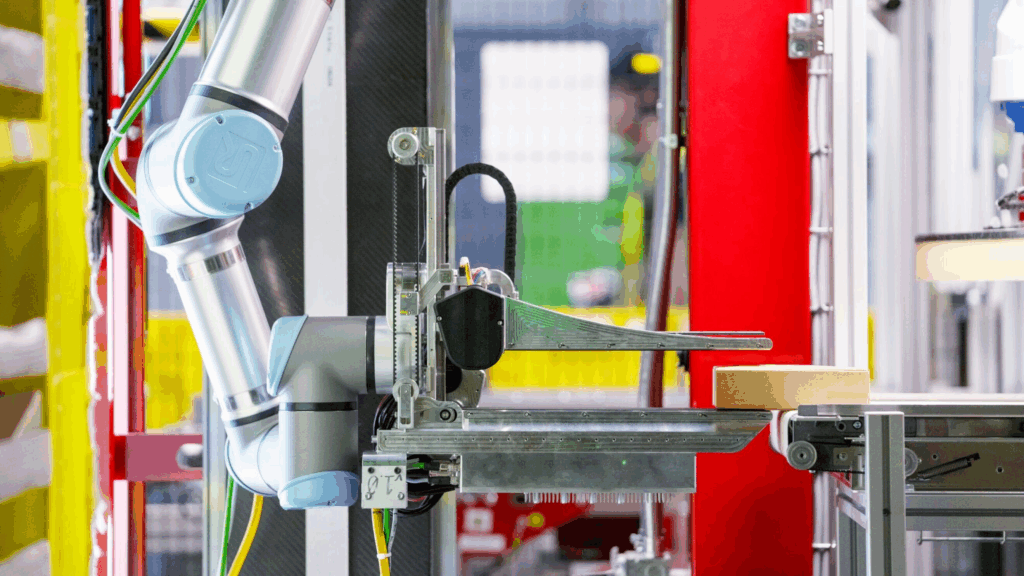

Amazon Robotics has unveiled a robot that boasts a sense of touch, marking a major advancement in robotics. Named Vulcan, this new technology was introduced at Amazon’s “Delivering the Future” event in Dortmund, Germany. Vulcan promises to enhance Amazon’s vast warehouse operations by improving the interaction between robots and items in the warehouse, enabling the automation of previously impossible tasks. The integration of AI allows Vulcan to identify and handle objects by touch, an exciting step forward in Amazon’s quest to streamline and automate its distribution process.

What’s Happening & Why This Matters

Amazon’s new robot, Vulcan, is not just about seeing the world; it’s about feeling it. Aaron Parness, Amazon’s Director of Robotics, described the Vulcan robot as a “fundamental leap forward in robotics.” Unlike Amazon’s previous machines, Vulcan can identify objects by touch and determine how to pick them up using AI. This leap is crucial in automating warehouse functions where human workers had to rely on physical effort and tools like ladders.

Vulcan is set to work alongside human staff who manage the picking stations, with robots handling items and shelving units. This new system will significantly reduce physical strain for workers. Robots will now stow items in the upper and lower levels of shelving units, eliminating the need for workers to climb ladders or frequently bend. These robots will coordinate with over 750,000 existing robots currently operating in Amazon’s facilities globally. These robots are used for moving and sorting items, as well as using suction cups and computer vision for specific tasks.

However, the rise of these technologies has raised concerns about job displacement. As robots become more adept at performing repetitive tasks, workers will be required for these operations. Goldman Sachs economists estimate that 300 million jobs worldwide could be lost by 2030 due to the rise of generative AI and automation technologies like Vulcan. While these developments are exciting, they also present challenges for global labor markets, especially in the distribution and retail sectors.

Yet, despite these concerns, Tye Brady, Amazon’s Chief Technologist for Robotics, believes that robots will never fully replace humans in Amazon’s warehouses. Instead, the robots amplify human potential by taking over the menial, mundane, and repetitive tasks. According to Brady, the human factor will always be essential to Amazon’s operations. Humans will be needed to bring common sense into decision-making, address unforeseen issues, and spot potential system vulnerabilities, such as hacking or errors during the sorting process.

Moreover, machine learning is empowering Amazon’s robots to navigate complex spaces and learn to move safely alongside people. With capabilities like the ability to ask, these robots can now continuously learn and adapt to new tasks.

In addition to Vulcan, Amazon invests in bespoke packaging technology designed to reduce waste through automation and machine learning. The company plans to install 70 machines across the UK, Germany, France, Italy, and Spain by the end of this year, with more installations set to follow by 2027.

This technological leap not only boosts Amazon’s efficiency but raises the bar for deeper automation across the industry. As Amazon pushes the boundaries of automation and robotics, it will keep expanding its efforts to implement AI-driven systems throughout its logistics operations.

TF Summary: What’s Next

Amazon’s Vulcan robot represents an exciting evolution for warehouse automation. While concerns about job displacement persist, Amazon focuses on using robotics to complement human work rather than replace it entirely. As robots take over repetitive tasks, human workers will focus on more complex aspects of Amazon’s operations, contributing their unique skills where AI falls short.

With new automation technologies, Amazon is poised to enhance its operations significantly. Expect continued advancements as the company focuses on integrating even more AI-driven systems to automate various aspects of its vast logistics network. Introducing Vulcan and other automation systems is vital to the future of warehouse operations and supply chains worldwide.

— Text-to-Speech (TTS) provided by gspeech